The practice of innovation

Here is how we help ambitious organizations make impactful new products, devices and experiences.

Design is not skin-deep. Our architecture-first approach cuts to the heart of the industrial design problem and leads to head-turning outcomes.

We develop meaningful form-factors derived from deep consideration of the conceptual and mechanical relationships between components and user interactions.

Design is like an iceberg, that exposed 10% is all you see. Whether physical or digital, it is responsible for ultimately communicating with the world. We give it something to say.

We’re not convinced that trained operators and early adopters are less deserving of visually appealing tools. Even the most automated of machines are destined to be seen and lived with in some capacity.

Good design is a catalyst for your technology and the not-so-secret weapon behind the most successful devices in our lives.

Working on something? Find out how industrial design can support your program’s goals.

Customers never forget — or forgive — a bad user experience. Our approach to workflow, communication, feedback, and human factors result in experiences that speak for themselves.

Through surveys, interviews and field observation we are able to craft better problem statements and extract more useful insights into the needs and expectations of customers.

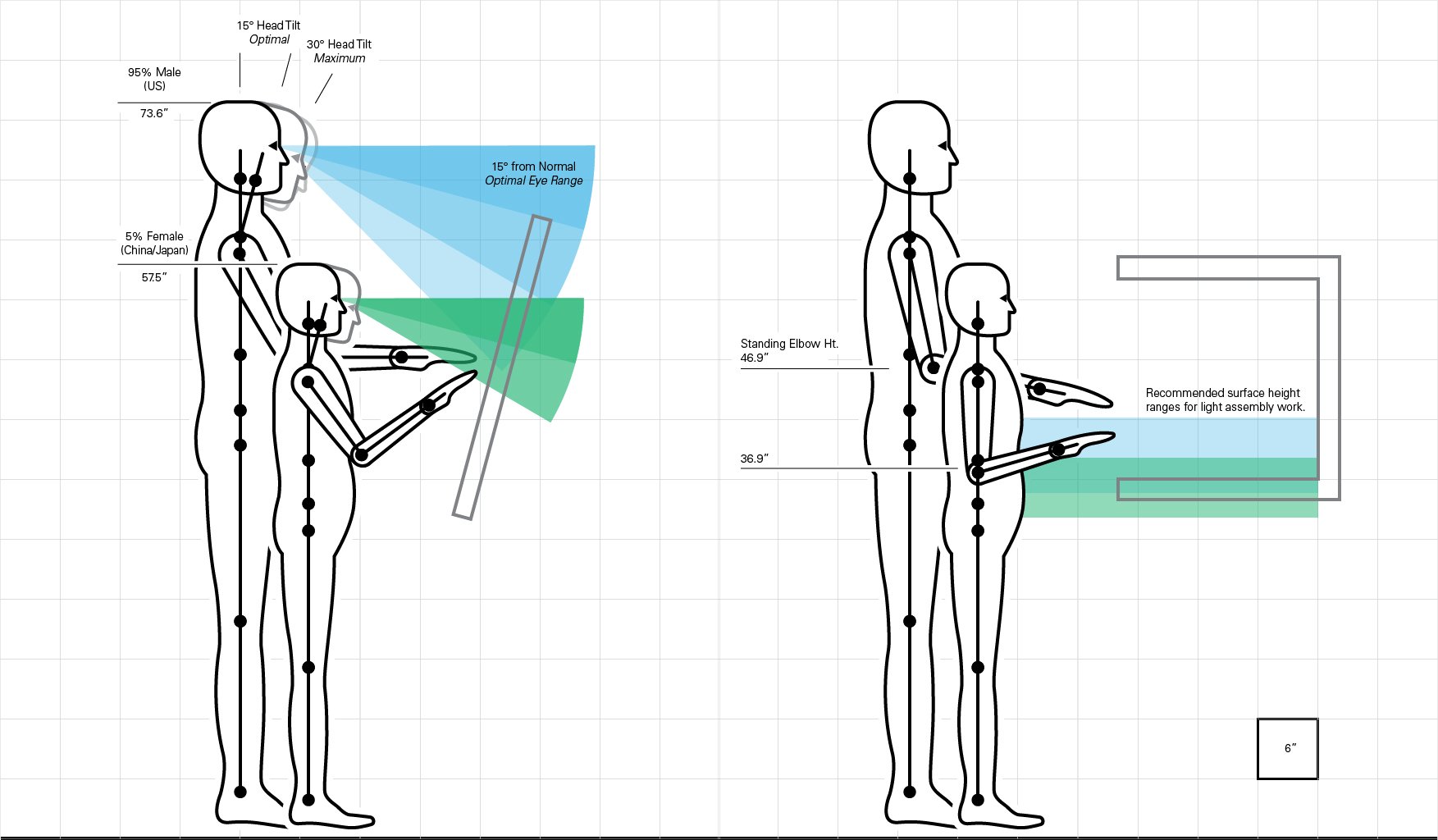

Human-centered design hasn't been made irrelevant with ai and robotics, only less obvious. We know where to push and pull to make a design more ergonomic, more comfortable, and more intuitive

The experience begins long before a device is actually plugged in and switched on. Our approach to design is holistic, we're thinking about the object, the software, the packaging, the instructions... usually simultaneously. The result is a streamlined user experience and life-long relationships with customers.

Making, testing, and refining is central to any design process. That's why we handle prototyping in-house. If we can't do something ourselves, our expansive network of manufacturers can.

Iteration is the backbone of the new product development process. Our in-house prototyping abilities let you move quickly and thoroughly from low fidelity ideation through to convincing, test-ready prototypes of finished designs.

We have designed for a dizzying array of production methods and materials. From extruded aluminum to injection molded polymers, stamped metal and soft-goods, we have the manufacturing experience to turn any idea into reality.

Navigating production, finding suppliers, inspecting samples, and getting out into the world is not the time to wing it. From prototypes to low volume ramping up, to full market production, you can rely on our fluency with the manufacturing process.